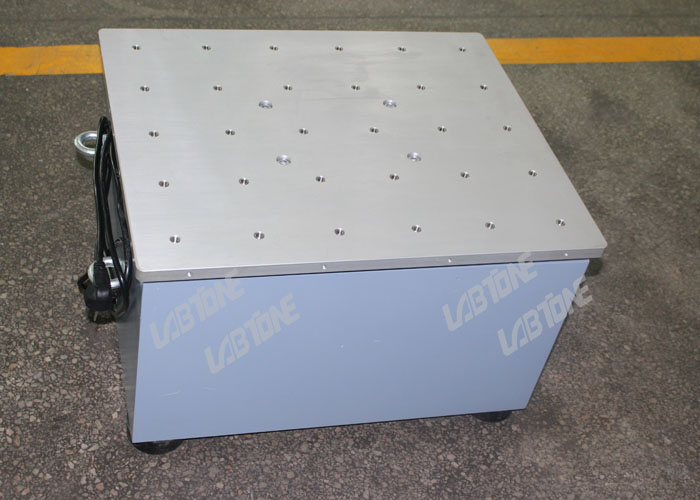

Labtone Test Equipment Co., Ltd. is a +20 year China manufacture of reliable, cost-effective

equipments . Our superior products mainly include: Vibration Test

Systems, Shock Test Systems, Bump Test Machine, Drop Tester,

Transportation Simulators, Combined Environmental Test Chambers.

Labtone started business in 2002 in a plant located in Shenzhen and moved

to our new, expand 6,000 square meter facility in Donguan,

GuangDong in 2015.Today, Our products are found around the world in

electronics, automotive,automotive,aerospace,telecommunication,

optoeletronics instrument and industrial machinery applications.

Our experience, and commitment to new product development, has

resulted in products that are easy to use,accurate and designed for

decades of service

Labtone products carry a one-year(12months) Warranty and are available

direct from our factory in Dongguan, China. We provide

comprehensive factory service and support,technical literature,

manuals and guides as well as having a qualified staff of experts

to help solve your application issues.

We sincerely invite you to visit our factory.