1. External Environmental Conditions

Ambient temperature: 0°C~35°C , RH: 85%,Ambient pressure: normal

atmosphere

Power supply: 380V±10%,50Hz+N+G,RG: ≤4 Ohm

2. Main characteristics of temperature and humidity

► Temperature Range:-40℃~+150℃

► Temperature Constancy:≤ ±0.5°C

► Temperature Uniformity: ≤ 2℃;

► Temperature Deviation:≤ ±2°C

► Temperature rate of chang(Measured at 20±2°C of ambient

temperature, averaged throughout)

Heating rate:+20℃→+150℃ ≥3℃/min;(No load, average throughout)

Cooling rate:+20℃→ -40℃ ≥2℃/min;(No load, average throughout)

► Humidity range:10%~98%( See below temperature and humidity range

chart, no heat dissipation load)

► Humidity deviation: +2/-3±%RH( > 75%RH) ±5.0%RH(Humidity ≤75%RH)

► Humidity uniformity:≤+2/-3%RH(>75%RH时)≤±5%RH(≤75RH)

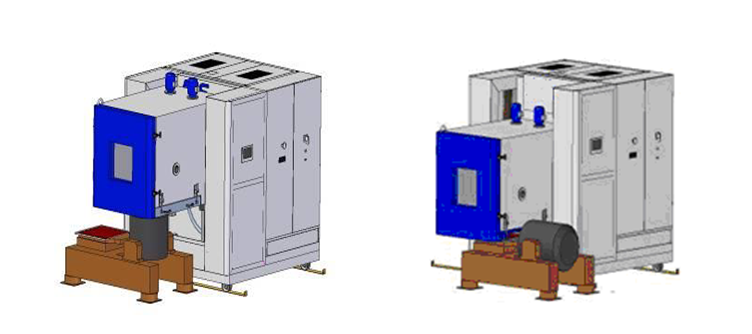

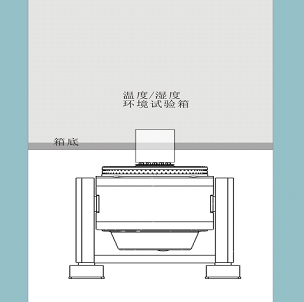

3. Main features of size

► Internal effective volume:about 2000L

► Inner size:1400 x 1400 x 1000mm (W x D x H)

► External dimensions of the chamber:about 3900 x 2400 x 2800 mm (W

x D xH) (Subject to the final design)

► With the vibration table size:slip table≤1000 x 1000mm;Head

Expander≤1000 x 1000mm

4. Refrigerating system

► The mechanical cooling is provided by a cascade system, which is

realized by two advanced piston compressors. The main body is made

of special cast iron, easy-to-integrate cylinder and light metal

alloy piston.

The cooling system has an automatic compressor protection system,

and an injection system can be used to protect the compressor

during cooling from high temperatures. This system can

self-regulate the cooling system of the compressor.

► Cooling method: air cooling.

► Refrigerant: Use environmentally friendly refrigerants R404A and

R23 that are not prohibited by the Montreal Convention or the

London Amendment and the new US Environmental Protection Agency

law.

► Energy-saving adjustment mode: cold-end PID adjustment mode (that

is, heating without cooling, cooling without heating), which saves

about 30% of energy than the balanced temperature adjustment

method. The cooling capacity can be adjusted intelligently, and it

can be adjusted automatically according to the temperature state,

so as to quickly realize the temperature change and temperature

balance. Compared with ordinary heat and cold balance control, the

temperature response speed is faster, the power consumption is

lower, the temperature deviation and fluctuation in the box are

smaller, and the temperature overshoot is effectively avoided

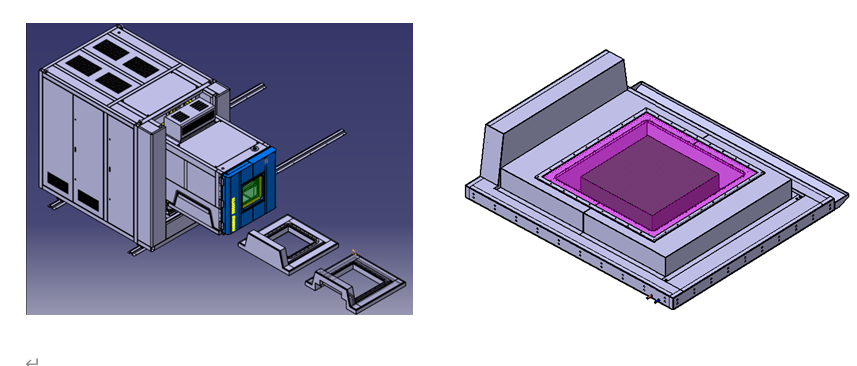

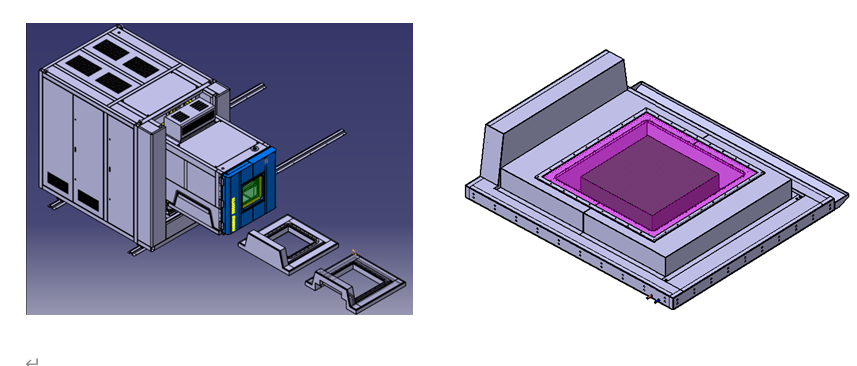

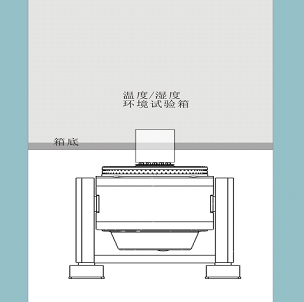

► Chamber bottom plate:

Three special movable bottom plates are used to connect the

chamber:

One is the bottom plate with holes, which is used for vertical

vibration;

One is a bottom plate with a square hole, which is used when it is

used with a horizontal slip table;

A blind plate, used when not shaking.

There is a condensate drain groove on the bottom of the shaker to

prevent the condensate from flowing into the shaker.

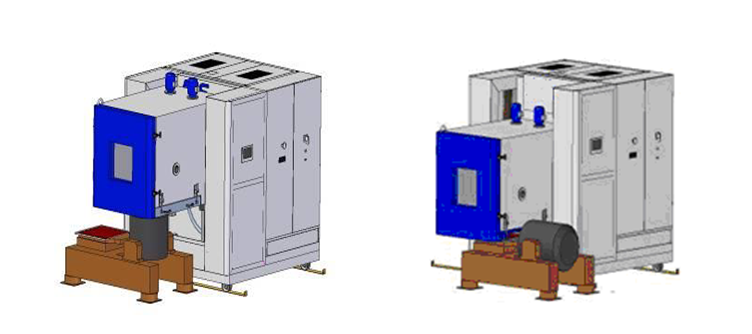

► The fit of chamber and shaker

With the head expander and with the slip table

Any special requirement please feel free to contact us, we will try

our best to realize it.

Connection mode:

Vibration test systems and test chamber connect directly

Vibration test systems and test chamber connect through transition

connector

Vibration test systems and test chamber connect through the table

Vibration horizontal direction connedted with chamber

Customer Services

Presales:

- Technical consultation: test method, laboratory planning and

suggestion.

- Equipment selection: selection scheme, FAQ.

- Product testing scheme.

In-Sales:

- Customer communication and progress report.

- Guidance for pre-installation preparation, equipment commissioning

and test run.

- Calibration (when Third Party’s verification is required).

After-Sales:

- Technical training: operation of equipment, daily maintenance,

common fault diagnosis and troubleshooting.

- Scheduled on-site service: Detection of problem as soon as possible

in order to eliminate equipment and anthropogenic hazards. This is

to ensure long term and stable equipment operation as well as

delivery of latest technical information.

- Technical support: special paid services are provided according to

customer’s needs.

Company Profile:

Labtone Test Equipment Co., Ltd. is a +15 year China manufacture of

reliable, cost-effective equipments. Our superior products mainly

include: Vibration Test Systems, Shock Test Systems, Bump Test

Systems, Drop Tester, Packaging Transportation Simulators, and

Combined Environmental Test Chambers.

Labtone started business in 2002 in a plant located in Shenzhen and

moved to our new, expanded 6,000 square meter facility in Dongguan,

Guangdong in 2015. Today, our products are found around the world

in electronics, automotive, aerospace, telecommunication,

optoelectronics instrument and industrial machinery applications.

Our experience and commitment to new product development has

resulted in products that are easy to use, accurate and designed

for decades of service.

Labtone products carry a one-year(12months) warranty. We provide

comprehensive factory services and supports, technical literatures,

manuals and guides as well as having qualified staffs and experts

to solve your problems.

We sincerely invite you to visit our factory.